METALS:

- Maintaining close tolerances is our specialty

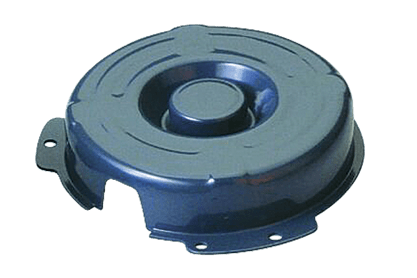

- Capable of manufacturing housings with concentricity’s of 0.003” or less. This leads to excellent air gaps & less than 0.006” T.I.R.—which eliminates noise & vibration issues

- By holding bearing pockets to a total 0.001” diameter tolerance, Boehm can minimize bearing pound out, resulting in extended bearing life.

- Metal Stamping Press Sizes - 85 to 2200 ton

- Metal Part Weights – ¼ lb. to 8000 lbs.

- Products manufactured: Chassis, Powertrain, Cab, Driveline and Structural components and subassemblies/assemblies

- Our full assemblies for automotive include water and oil engine pumps, radiators, drivelines, fasteners, leaf springs, and shock absorbers

Our metal processes include:

Forgings:

- Closed Die

Extrusions:

Stampings:

Castings:

- Gravity Die Casting

- High Pressure Die Casting

- Investment Casting

- Shell Mold Casting

- Low Pressure Sand Casting

- Permanent Mold Casting

- Squeeze Casting

- Low Pressure Semi-Permanent Mold Casting

Our FINISHING processes include:

- Machining

- Turning

- Ultrasonic Testing

- X-Ray Testing

- Cleanliness Testing

- Leak Testing

- Parts Washing

- Parts Marking

- Warehousing

- Assembly